|

Shanghai HengQiao Machinery Technology Ltd.,Co

|

Drilling and Piling Rotary Drilling Rig

| Price: | 169210.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shanghai, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Maximum output torque(KN.m): 160 Max.

drilling depth(m): 55 Max.

drilling diameter(mm): 1500

Brand Name: HENGQ

Model Number: HQR160Z

HQR160Z Professional Construction Rotary Drilling Rigs

Drilling machine HQR160Z rotary drilling rig Features

Drilling machine HQR160Z rotary drilling rig Features

• Main winch located at the bottom of the drilling mast which offer good angle foe checking line's work. Unique design in the line roll could prolong the use life of the steel line and also enhance the construction safety.

• Hydraulic system adopts advanced load-feedback technology. Realizing hydraulic liquidity allocate to different parts according to the operation demand. Top key parts guarantee high reliability, such as pump, motor, valve, pipe and joint come from international top brands.

• Configuring CAT336D undercarriage and up structure. The crawler could adjust between 3000mm and 4300mm. The customers could backward the counterweight and increase its weight also for improving the stability and reliability.

HQR160Z Drilling Rigs Technical Parameters

| Model | HQR160Z Rotary Drill Rig |

| Rated output torque | 160KN.m |

| Max.output torque | 55m |

| Max drilling diameter | 1500mm |

| Engine brand | Cummins |

| Engine model | Cummins QSB 6.7-C220 |

| Engine power | 164KW |

| Traction force | 345KN |

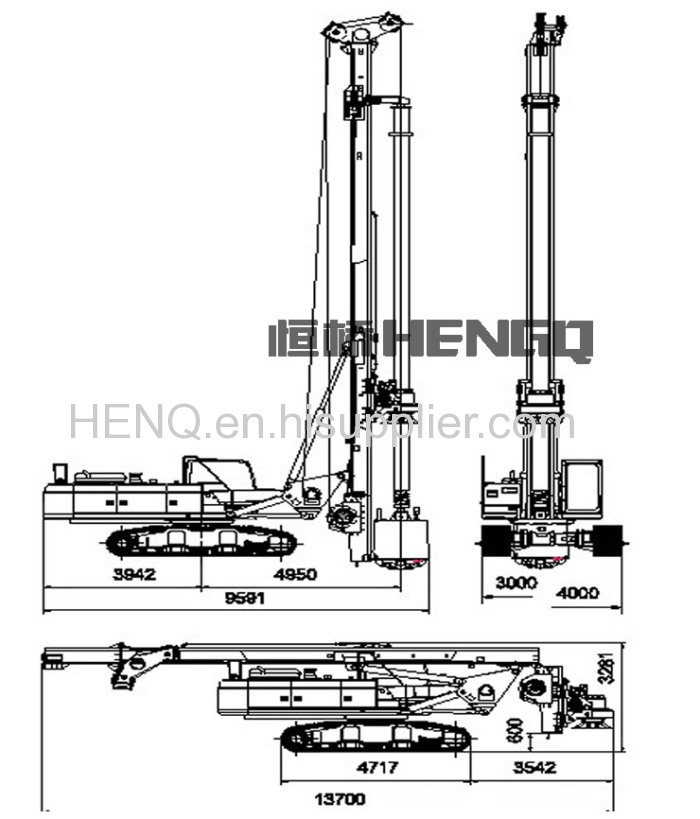

| Overall L/H/W transport pcsition | 13700/3000/3281mm |

| Total weight | 45/53t |

HQR160Z Drilling Rigs Construction Case

Introduction to Rotary Drilling Machine:

CAT Undercarriage & Up Structure

HQR series rotary drill rig have excellent design concept, reliable system, strong power and self-extendable undercarriage which insure operation in complicated jobsites. Heavy hydraulic telescopic crawler is very stable and flexible, especially suitable for narrow jobsites. HQR series rotary drill rig enjoy economic, efficient, environment friendly, stable performance and other features.

Power System

Original CAT EFI engine has strong power and strong torque. Electrical fuel direct injection turbo intercooler merged with HQR core technology in electricity system which ensures the engine produces strong power in each gear. HQR Rotary Drill Rig could save 10% fuel consumption comparing the same model equipment under the same work condition.

Hydraulic System

HQR series rotary drill rig absorb international advanced design concept, use top international brands for key parts, hydraulic pilot, scale operation. Advanced main & auxiliary hydraulic system realizes flow allocation & sensitivity loading according to the operation demand and also the drive function. These features offer more reliable, more economic, higher efficient and more energy save in the construction process.

Electricity System

The key parts in electricity system come from Germany or Fenland famous brands. Professional construction machinery controller adjusts and controls the engine, pump, main valve and operation handle's work. At the same time, the electricity system realize efficiency, energy save and low pollution for the equipment.Unique design in intelligent inspection system has the ability to check the malfunction reason.High precision sensor insures drill rig's precision measurement and inspects whole work process.

Drive Device

HQR series rotary drill rig adopt professional rotary table which equips BONFIGLIOLI or BREVINI reducer. Heavy damping spring, different kinds of multilevel shock absorption design grantee safe operation.

Construction Method

HQR has professional team to support our customer to select the right equipment model. The Kelly Bar and tools configuration based on the earth structure and construction requirements so as to improve the work efficiency and avoid damage to the equipment.

Our Service

Service Tenet

Perfect aftersales service system is the firm guarantee to maintain the brand image. We will build perfect aftersales service system and provide optimal aftersales service for each product. Mutual development and perfection is our aftersales service tenet.

Delivery Inspection

When the customer has finished the purchase process, our service staff will provide maintenance and operation training, and the warranty sheet should be faxed to HQR.

Regular Check

We provide regular check for all our products respectively at the 50, 500, 1,000, 1,500, and 2,000 hours. And the service staff will make thorough inspection and repair for the equipment according to the follow-up visit to the customers.

Warranty service

As for the service range, please refer to the Warranty Manual. We carry out the 24-hour service principle, i.e. we will solve the problems or replace the damaged parts in 24 hours. We will solve the problem thoroughly and ensure that it does not need the secondary repair.

Our service staff will fill in the service report and fax it to the service department in 24 hours.

Parts inventory

Each dealer will reserve some parts inventory according to their sales condition and all the parts are provided by HQR.

Cross-region service

When the equipment needs to work in other regions that is out of the reach of the designated dealer, the dealer will inform the factory to arrange other dealers to make the follow-up services.

Return visit

The service staff needs to establish detailed customer files and pay a return visit to the customer each week to learn about the equipment condition.

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

-

6 Ton Cable Tension Stringing Equipments with German Rexroth Hydraulic pumpSA-YQ60 SA-YQ90 SA-YZ30A SA-YZ2X35